1.SCAN

The scan machine will collect data and make a label about the slab, then you can use your phone to scan the label. The details about the slab will be presented, which is including the pattern, size and name of the slab.The scan machine will also create high quality images with clear texture and colour.

2.SOFTWARE

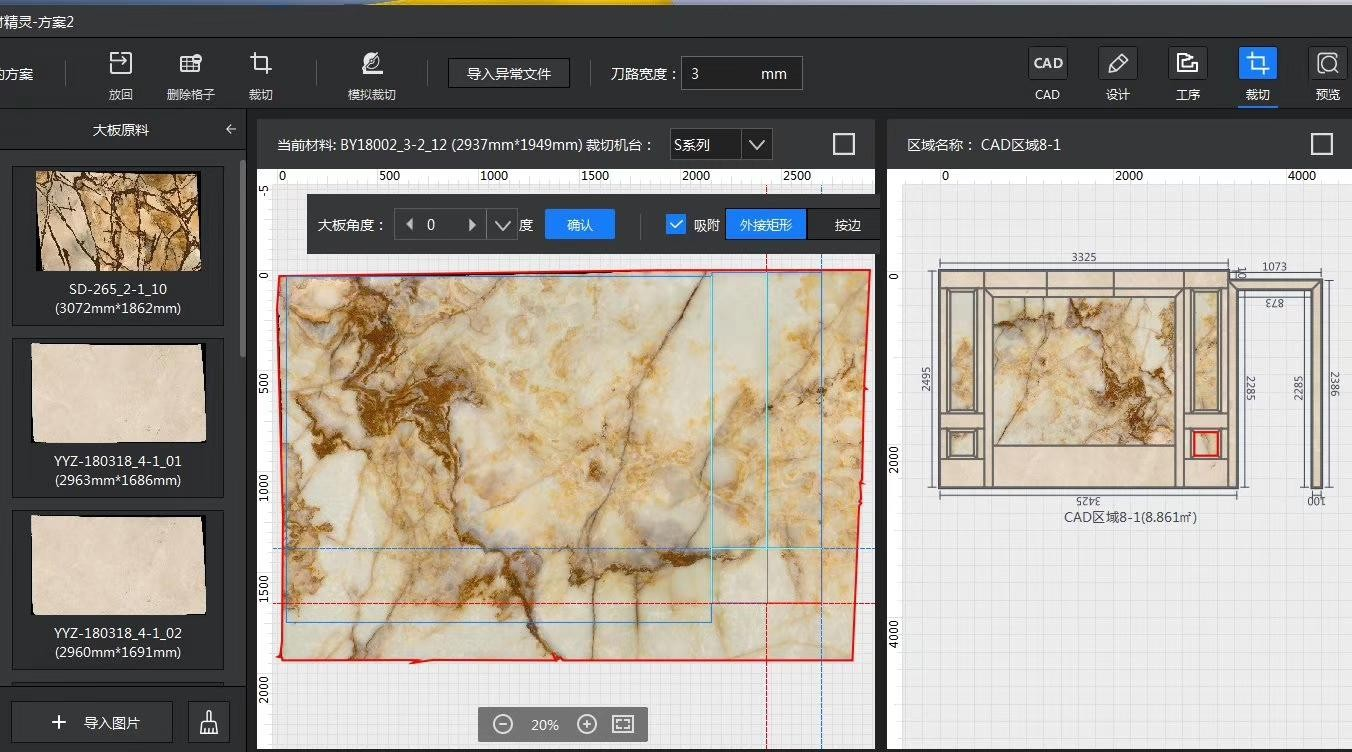

The CAD will use the images to design the plan of intelligent cutting by intelligent software, which can realize function of texture tracing and pattern alignment.The intelligent software can also calculate the recovery rate of material.

3.CUSTOMER

Then the cutting plan will be sent to customer to confirm. If the customer is not satisfied with the cutting plan, then they can negotiate with us how to use the slabs effectively.

4.CREAT

After that, the CNC cutting plan will be created.

5.INTELLIGENT CUTTING

The CAD will sent the cutting plan to the worker, then they will use the intelligent cutting machine,such as C500, E500 and S600 to cut. There are 6 intelligent bridge cutting machines in our factory, ranking first in the industry.

6.FINISHED

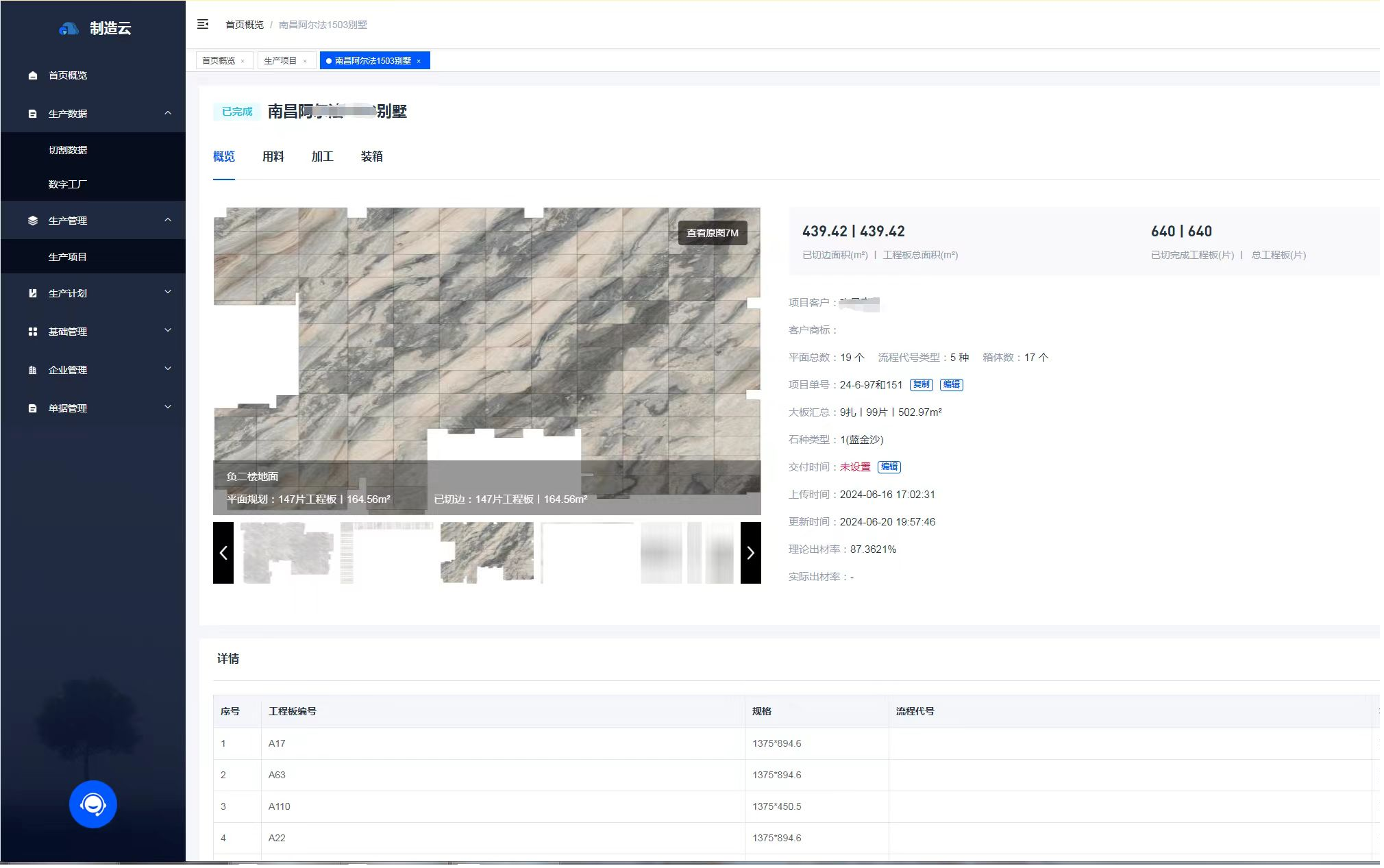

7.PRODUCTION MANAGEMENT SOFTWARE

The customers can check the processing procedure by using the production management software, which is developed by Ruifengyuan Stone independently.

8.INSPECTION & DELIVERY

The worker will check and inspection before delivery,

DIFFERENCE BETWEEN TRADITIONAL AND INTELLIGENT PROCESSING METHOD

In the traditional processing method, layout and colour matching are relied on the imagination and memory of human, which is a waste of time and effort. It is impossible to achieve effects such as texture tracing and texture alignment. The beauty of stone color and texture cannot be perfectly presented.

Conducting online pre-cutting and pre-arranging with the images from the scanner can easily achieve the effect of texture tracing and pattern alignment. AND Create a stone design solution for customer to confirm, which can improve the yield and help customers to save costs. Every product can be tracked and managed with an independent and exclusive QR code, and the color and texture can be automatically identified.

Post time: Nov-29-2024